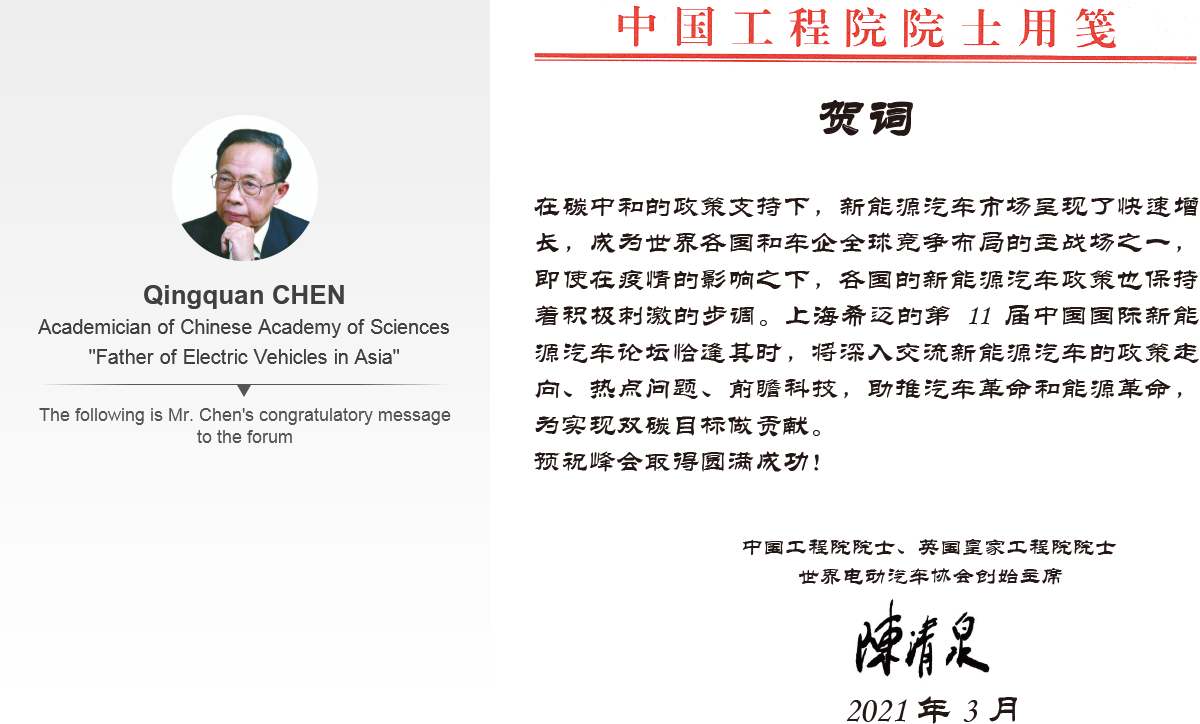

Globally, although the automotive industry has gradually changed in the past few years, the new trend of vigorous development of new energy vehicles has become increasingly prominent. In addition, policymakers in many countries have increased their support for new energy vehicles, and the investment, research, development of new energy vehicles by major international auto giants have also increased significantly. At present, under the pressure of the new crown pneumonia epidemic, new energy vehicles are entering a critical point of development, and may become the "main comprehensive point of view of the global competition layout of countries and car companies in the world. In terms of the development of new energy vehicles, many countries have adopted an encouraging position: one of the battlefields. Under the epidemic situation, governments of various countries have increased the supplementary efforts of new energy vehicles, thereby serving as a starting point to boost the economy. Even successively introduced various support policies, and vigorously promoted the technological upgrading and market promotion of new energy vehicles. Even under the influence of the epidemic, the new energy vehicle policies of various countries have maintained a positive stimulus pace.

|

27th May Morning |

Main Forum + Awards Ceremony | ||

| Forum Time | Battery Forum | Thermal Management Forum | Powertrain Forum |

| 27th May Afternoon | Fuel Cell and Hydrogen Energy | Vehicle Thermal Managementand Its New Direction | Powertrain Electric Drive Integration |

| 28th May Morning | Power battery R&D and Charging’s technology trends | Air-conditioning and core three electric heating management and response and prevention of thermal runaway | Innovation and Application of Electric Motor Control and Key Materials |

| 28th May Afternoon | Development and Iteration of Powertrain Components | ||

> Weidong ZHANG, Project Director, UNDP;

> Pin GAN, Deputy Director of Science and Technology Commission of Shanghai Municipality;

> Jing MA, Deputy Director of Shanghai Municipal Commission of Economy and Informatization;

> Huadi SHEN, Deputy District Mayor of Shanghai Jiading District Government;

> Guangjun Zhao, Deputy Director of Shanghai Economic and Information Committee;

> Dongsheng XIE, Deputy Mayor of Anting Town, Jiading District, Shanghai;

> Jinming NIU, Director, Beijing New Energy Vehicle Development Promotion Center;

> Qingquan CHEN ,Chinese Academy of Engineering, the British Royal Academy of Engineering;

> Rui WEI, Senior Vice President of China R & D, BMW Group;

> Shaoyong NI , Deputy General Manager of Chery New Energy Automotive Technology Co., Ltd.;

> Ming KANG, Dongfeng Commercial Vehicle Technology Center Institute of Technology;

> Xiong Fei, Deputy General Manager of Changjiang EV R&D;

> Xiang GAO, China Public Relations Policy and Charging Infrastructure Director at Tesla;

> Dong ZHANG, Director of BEV Platform Passenger Vehicle, SAIC Motor;

> Kangcong XU, Vehicle Chief Engineer at Beijing Automotive Research Institute;

> Chunlin ZHANG , Minister of New Technology and Materials, BAIC Research Institute;

> Pingsheng XIE, Electronics Division Director at BYD Automotive;

> Bin HE, Director of EP Architecture and Control, NIO;

> Gary Denton, Director, Shanghai NIO Motor Co., Ltd.;

> Ingo von Wurmb, Director of Stamping, BMW Brilliance Automotive Co., Ltd.;

> Juergen BAUER, Project Manager, Joint Laboratory of Audi-Tongji;

> Simon STEVENS, Jaguar Land Rover China Engineering and Project Director;

> Gert Hildebrand, Vice President of design at QOROS;

> Neil Robson, Chief Engineer, Electric Control Division, Changan Automobile UK R & D Center;

> Damian Szegda, Chief Computations Officer Impression Technologies Ltd.;

> Iida Hirokawa, General Director Assistant Development Group Headquarters Mitsubishi Electric Industrial Co., Ltd.;

> Mirko FRANKE, Engineering Director, Bosch Automotive Chassis Control Systems China;

> Heiko WELLER, Electric Vehicle Project Director Bosch Engineering Technology Co., Ltd.;

> MaryAnn WRIGHT, Vice President of Business Technology and Innovation at Johnson Controls Energy Power;

> Robert Galyen, Chief Technology Officer, CATL Times New Energy Technologies;

> Sigmund Gronich, former senior US State Department of Energy;

> Stefan Rosenwald, CEO of Daimler Protics Gmbh and so on.

......

Huawei

Founded in 1987, Huawei is a leading global provider of information and communications technology (ICT) infrastructure and smart devices. We are committed to bringing digital to every person, home and organization for a fully connected, intelligent world. We have approximately 197,000 employees and we operate in over 170 countries and regions, serving more than three billion people around the world.

GOM

GOM develops, produces and distributes software, machines and systems for

industrial and automated 3D coordinate measuring technology and 3D

testing based on latest research results and innovative technologies.

With more than 60 sites and an employee network of more than 1,000 metrology

specialists, GOM guarantees professional advice as well as support and service

to operators on-site in their local languages. In addition, GOM shares knowledge

on processes and measurement technology in training courses, conferences and

application-based workshops.

Company WebSite:

www.gom.com/cn.html

Marposs

Marposs was established in Bologna in 1952. As a leading global supplier of

precision metrology equipment for improving productivity and reducing cost in

manufacturing, Marposs supply inspection, measurement and process control solutions.

Marposs productions are mainly applied to Automobile, Machine, Compressor, Glass,

Computer, Electromotor Industries etc. Marposs productions include gauges and

compensation systems for grinders and other machine tools; manual gauges,sensors,

probes and other gauge components; automatic measurement and inspection systems;

hardware and software for data collection and process analysis; equipment for

non-destructive testing; transfer line for machining line, general assembly line,

Sub-assembly line, special machine, accessory equipment and measuring machine for

automobile industry.

Marposs China set up headquarter and manufacturing plant in Nanjing ,

and sales and after-sales service in Shanghai ,Beijing ,Guangzhou , Wuhan etc.

Company WebSite:

www.marposs.com/chi

Poppe + Potthoff

Poppe + Potthoff stands for precision and technology. With our ingrained passion for

constant innovation and customer centricity, we continue to supply cutting-edge

technology companies with core components for their offerings and create value with

and for our customers.

As a proven First-Tier supplier of the automotive industry Poppe + Potthoff designs

and manufactures subsystems for fuel cells, H2-combustion engines and dual fuel

engines, e.g. rails, high pressure lines, tubes, filters, valves and hydrogen

distribution bodies for its combustion engine manufacturer clients.

Our solutions enable high hydrogen pressures up to 700 bar. Furthermore,

we have also developed a material group especially designed for hydrogen injection

lines. P+P is able to deliver this broad range of components for various powertrain

technologies in the fields of automotive, maritime as well as stationary or

mobile applications – both for small and high performing engine purposes.

As a group of companies, our in-house expertise and capability ranges from

the development of components, to various validation processes and manufacturing in

our own production facilities. To optimize our products and ensure their quality

right from the development stage on, our subsidiary Poppe + Potthoff Maschinenbau

offers sophisticated solutions for measuring the strength and durability of

components with its inhouse developed and produced special machines,

designed for pressure cycle testing, burst and function testing.

For hydrogen applications in particular, these machines allow to test

the strength and function of media carrying components e.g. valves, pipes,

pressure cylinders, storages and other parts. Our machines can also

be used to put cooling and heating systems in the field of e-mobility to the test,

in order to ensure a flawless thermal management necessary for the

electric vehicle when adapting to varying environmental influences.

Company WebSite:

www.poppe-potthoff.com

SHERPA ENGINEERING

Sherpa Engineering is a French company specialized in modeling,

simulation and control design. We are not only an engineering services company,

but we are also a specialized tool developer. Our tools are based on models and

libraries built during 20 years working in the automotive, aerospace and

energy sectors. Our mission is to support our customers in deploying a

methodology based on models and on our specialized tools,

which capitalize on our experience from hundreds of projects.

Company WebSite:

www.sherpa-eng.com

Feilong Auto Components Co., Ltd.

Feilong Auto Components Co., Ltd. established in 1952 with the registered

capital 0.5 billion RMB and total assets 3.66 billion RMB. It listed on

the Shenzhen Stock Exchange in January 2011(stock code 002536).

The leading products are automobile water pump, turbine housing,

thermal management control valve, electric water pump, and vacuum pump, etc..

At present, the company has more than 4300 employees, and has an

annual production capacity of 10 million mechanical water pumps, 1.5 million

electric water pumps, 1.2 million thermal management control valves and

6.5 million turbine housing castings. There are more than 7000 sets production,

test, and inspection equipments, and has the domestic industry leading position

for development and production capacity. The company has 137 domestic and

foreign customers, serves 208 bases and plants in around the world.

Company WebSite:

www.xixia-waterpump.com

Shell

Shell is one of the world's largest energy and chemical companies with operations

in more than 70 countries and territories, ranks in the top three

in the Fortune 500, is one of the world's largest lubricant producers and

suppliers, is one of the world's largest fuel suppliers and gas station networks,

and by 2015 it has provided a total of more than 3,000 lubricants to a wide

range of automotive consumers and industries in more than 100 countries.

Shell Lubricants has the world's largest market share for 13 consecutive years.

Shell E-Fluids brand, for new energy pure electric vehicle split and integrated

transmission systems, respectively, the introduction of the E5 series and

E6i series of two product systems, has been with several major domestic host

plants to test, some products have been put into batch supply. In view of the

integrated transmission system of new energy hybrid vehicles, special

requirements such as friction performance of synchronizers are taken into

account, and DHT series of professional transmission oils are developed in

addition to meeting the technical requirements of the host plant.

Company WebSite:

www.shell.com

IDI Composites International (IDI)

IDI Composites International (IDI) is the premier global custom formulator and

manufacturer of thermoset molding compounds. The company provides customized

polyester/vinylester-based BMC, SMC, and a new line of Structural

Thermoset Composites (STC).

With wholly owned manufacturing operations in every region of the world,

including a 12,300 square meter facility in Jinshan Shanghai, China,

IDI is a global partner to OEMs and Tier 1s who can rely on

our substantial R&D resources, excellent chemical engineering,

ISO-certified manufacturing, and comprehensive quality control.

At IDI, our work with OEM and Tier 1 partners is focused on

“Ideas for Meaningful Results.” We take pride in listening to our partners’ needs

and then developing solutions that contribute to their success. Our FLAMEVEXTM line of

materials is the perfect example of this dynamic partnership in action.

OEMs came to IDI seeking an alternative to metal for EV battery enclosures.

We worked with them to develop a material that uniquely combines high strength and

high fire performance.

Today FLAMEVEXTM has been widely deployed and has been used on battery packs

which have passed the stringent Chinese Standard GB/T 31467.3 test.

It offers designers a strong, lightweight and cost-effective alternative to metals

traditionally used to enclose battery packs.

Company WebSite:

idicomposites.com

日立科学仪器(北京)有限公司

日立科学仪器(北京)有限公司是世界500强日立集团旗下日立高新技术有限公司在北京设立的全资子公司。本公司秉承日立集团的使命、

价值观和愿景,始终追寻“以成为先端技术领域里提供高科技解决方案的全球第一为目标”的企业理念,通过与客户的协同创新,积极为教育、

科研、工业等领域的客户需求提供专业和优质的解决方案。

我们的主要产品包括:各类电子显微镜、原子力显微镜等表面科学仪器和前处理设备,以及各类色谱、光谱、电化学等分析仪器。

为了更好地服务于中国广大的日立客户,公司目前在北京、上海、广州、西安、成都、武汉、沈阳等十几个主要城市设立有分公司、

办事处或联络处等分支机构,直接为客户提供快速便捷的、专业优质的各类相关技术咨询、应用支持和售后技术服务,

从而协助我们的客户实现其目标,共创美好未来。

Oxford Instruments plc

Oxford Instruments plc is a leading provider of high technology products and

services to the world's leading industrial companies and scientific research communities.

Our core purpose is to support our customers to address some of the world's most pressing

challenges, enabling a greener economy, increased connectivity, improved health and leaps

in scientific understanding.

Company WebSite:

www.51haocai.cn

上海西怡新材料科技有限公司

上海西怡新材料科技有限公司成立于2009年,是日本信越化学工业株式会社在中国的授权代理商。公司销售全品类的各种硅胶产品,

包括:粘接剂、密封胶、硅橡胶、各种形态的导热材料、硅烷偶联剂和阻燃剂等;同时也销售非硅类的粘接产品。

我们的产品在汽车工业有广泛的应用,包括燃油汽车,锂电池新能源汽车,以及燃料电池汽车;在汽车电子领域,整车装配领域,

以及汽车塑料改性领域均有应用。

我们以一流的产品,专业的服务,为客户提供全方位的汽车硅胶材料的解决方案,为客户的创新提供价值,助力未来。

Company WebSite:

www.taayuu.com

ExxonMobil

ExxonMobil, one of the largest publicly traded international energy companies,

uses technology and innovation to help meet the world’s growing energy needs.

ExxonMobil holds an industry-leading inventory of resources,

is one of the largest refiners and marketers of petroleum products,

and its chemical company is one of the largest in the world. To learn more,

visit exxonmobil.com and the Energy Factor. Follow us on Twitter and LinkedIn.

Company WebSite:

corporate.exxonmobil.com

Heraeus Electronics

Heraeus Electronics – a Global Business Unit of the Heraeus Group – is one of the

leading manufacturers of materials for the assembly and packaging of devices in

the electronics industry. The company develops sophisticated materials solutions for

consumer electronics and computing, automotive, LED, power electronics and communications.

Core competences include bonding wires, assembly materials, thick film pastes as well as

roll clad strips and substrates, and their integration into perfectly matched systems.

Company WebSite:

www.heraeus.com

ARaymond

ARaymond was established in 1865 in Grenoble, France. With more than 150 years of history,

there are 6,000 people in 26 countries working together, including more than 300 product

development engineers in 11 engineer design centers. ARaymond have around 1,600

active patents and it is one of the best suppliers for fasteners in the world.

ARaymond China was founded in 1996, with the idea to serve best our customers located in

China with fastening solution with Clips, Straps, Quick Connectors, Bonding solution, etc.

Our plant is located in Zhenjiang City, Jiangsu Province with up to 700 employees and

we have sales offices in Shanghai, Wuhan, Chongqing, Changchun and Guangzhou.

We are experienced in the automotive sector and have longstanding business relationships

with customers, like BMW, Benz, Ford, DPCA, SAIC, VW, GM, Adient, Lear, Hutchinson,

Faurecia, Valeo, Chinaust, etc…

Company WebSite:

dbfasteners.cn

Chroma ATE Inc.

Founded in 1984, Chroma ATE Inc. is a world leading supplier of precision test and

measurement instrumentation, automated test systems, intelligent manufacturing systems,

and test & automation turnkey solutions marketed globally under the brand name "Chroma".

Significant markets Chroma serves include electric vehicle, green battery, semiconductor,

photonics, LED, photovoltaic, flat panel display, video and color, power electronics,

passive component, electrical safety, thermoelectric, automated optical inspection,

and intelligent manufacturing system for ICT, clean technology, and smart factory industries.

Chroma has branch offices in Europe, the United States, Japan, Korea, China,

and Southeast Asia chartered to deliver innovative technologies with high value-added

service to satisfy our global customers' demands.

Company WebSite:

www.chromaate.com

SABIC

BASF

BASF is a leading cathode active material (CAM) supplier to battery producers for

electrified vehicles around the world. Research and development activities combined

with acquisitions have delivered a unique technology portfolio for lithium-ion batteries

including advanced high-energy density CAM such as Nickel Cobalt Aluminum (NCA) oxide and

Nickel Cobalt Manganese (NCM) oxide, which play a key role in determining battery

performance, energy density, service life and safety. BASF operates manufacturing and

R&D sites in Europe, Asian and the US near its customers. Our global battery materials

business, along with our research and development capabilities, enable us to provide

broad expertise to our customers in the development of new battery materials and products.

Further information on BASF’s Battery Materials is available on the Internet at

https://catalysts.basf.com/products-and-industries/battery-materials.

Company WebSite:

catalysts.basf.com

Teesing Industrial Systems (Beijing)Co.,Ltd. (for short TIS)

Teesing Industrial Systems (Beijing)Co.,Ltd. (for short TIS) is established in 2005,

a wholly-owned subsidiary of the parent company Teesing BV. Teesing B.V.

has built a sound international reputation as a technical wholesaler and

engineering company, since 1952. Principal markets are in Europe, Asia and the U.S.A.

The company has permanent offices in Beijing (China), New Jersey (U.S.A.) and

Zhubei City (Taiwan). The head office is located in Rijswijk,The Netherlands.

We have been involving in the Chinese market for high quality connection solutions for

over 16 years. We offer fittings, valves and regulators, tubing, systems and assemblies

for alternative energy, industrial applications and submicron technology.

As predicted, the global hydrogen demand are promising. In the Asia-Pacific region,

China will become the world's largest hydrogen market. Together with our partners WEH and

P+P we expect a bright future for the hydrogen economy development.

Based on extensive experience in NGV refueling systems, WEH has developed high-pressure

hydrogen refueling systems for hydrogen fuel cell vehicles and hydrogen fueling stations.

WEH as a pioneer in designing and manufacturing high-quality components for hydrogen

refueling and a partner of many OEMs, safety, ease of operation and the well-executed

design, makes WEH H2 products the number one choice worldwide. Today, most state-of-the-art

hydrogen fueling stations all around the world rely on WEH® Fueling nozzles and breakaways.

The latest hydrogen fuel cell vehicles of leading automotive manufacturers are

equipped with WEH® Fueling receptacles, check valves and filters. Thanks to intensive

research and development, WEH has become a reliable and valued partner to the automotive

industry in this cutting-edge technology.

As a sole distributor of WEH for the Chinese market, TIS has heavily involved in

the Chinese hydrogen fuel cell vehicle market for many years and has an extensive and

in-depth cooperation with many Chinese customers. WEH has also earned a good reputation

for its hydrogen refueling systems in the domestic market.

As the Representative of P+P highly integrated on-tank-valve for H2 gas, we will try our

utmost to perform well in the Chinese market.

With our continued innovation and in close cooperation with our partners WEH and P+P we

trust we can contribute to the domestic clean, economic and safe vehicle fuel market

development.

Company WebSite:

www.teesing.com.cn/cn

Vishay

Vishay manufactures one of the world’s largest portfolios of discrete semiconductors and

passive electronic components that are essential to innovative designs in the automotive,

industrial, computing, consumer, telecommunications, military, aerospace,

and medical markets. Serving customers worldwide, Vishay is The DNA of

tech.™ Vishay Intertechnology, Inc. is a Fortune 1,000 Company listed on the NYSE (VSH).

More on Vishay at www.Vishay.com

Company WebSite:

www.Vishay.com

Minitab

Minitab, LLC. delivers software and services for quality improvement and

process improvements. For more than 50 years, thousands of distinguished organizations in

more than 100 countries have turned to Minitab for tools that help quality initiatives

yield bottom-line benefits. Minitab statistical software is an undisputed market leader

in Lean Six Sigma statistics and Quality Analysis.

Company WebSite:

www.techmax.com.cn

Zhejiang Jinewell Automotive Lightweight Technology Co., Ltd.

Zhejiang Jinewell Automotive Lightweight Technology Co., Ltd. is a company specializing

in the production of wide&thin aluminum profiles. Its shareholders are composed of

three well-known aluminum factories in Jiangsu, Zhejiang and Shanghai.

The company was registered in April 2019, with a factory building of 60,000 square meters ,

registered capital of 100 million yuan.

For wide aluminum profiles, the general extrusion process is to use the round casting rod

for production, due to the limitation of extrusion ratio, the corresponding of producing

the minimum wall thickness is thicker, so it is difficult to extrude the wide and thin

profiles in the traditional aluminum extrusion, which brings great limitations to the

practical application.

Ginewell uses the small tonnage of flat extrusion method to overcome traditional pain

points of aluminum extrusion industry.For the first time , the difficulties of the

whole process of flat extrusion from equipment , mold to process of wide and thin

profile have been comprehensively solved , filling the gap in the industry of

directly squeezing ultra - wide and ultra - thin profile , so as to better serve many

emerging industries such as high - speed railway , automobile and 5 G、 electronics .

Shenzhen Jinke Special Materials Co., Ltd

Shenzhen Jinke Special Materials Co., Ltd is a High-tech enterprise specialized in new

functional materials and research, development, production and sales in related fields.

It is one of the first high-tech enterprise recognized by Shenzhen municipal government.

Jinzhang Electric Heating Component Co., Ltd is a branch company of Jinke.

As the largest and most complete PTC series products manufacturer in China,

its technical level has reach the international standard and the products are exported

to more than 30 countries. Jinzhang has been obtained the IATF16949 quality system

certification, and CQC, UL, TUV etc. certification. Which widely used in fan heater,

hand dryer, cloth dryer, air conditioner, vehicle heating, battery warmer and liquid etc.

Company WebSite:

www.szjinke.com

Zhejiang Changsheng Sliding Bearings Co., Ltd.

CSB(Zhejiang Changsheng Sliding Bearings Co., Ltd.)was established in June 1995. In 2017, CSB was successfully

listed on the Shenzhen Stock Exchange Market with a registered capital of 198 million RMB. It has three holding

subsidiaries, covering 17.4 hectares of land, a construction area of 145,000㎡, and more than 800 employees.

According to authoritative statistics, the company's operating income, total assets and other major operating

indicators in 2013-2019 shows that CSB ranked first in self-lubricated bearing industry for the past five years.

The company is a high-tech enterprise specialized in R & D, production and sales of self-lubricated bearings.

The main products are bimetal self-lubricated bearings, metal-plastic self-lubricated bearings, metal-based

self-lubricated bearings, plastic self-lubricated bearings, of which about 50% are exported to more than 40

countries and regions, such as European countries and the United States, Japan, mainly used in automobiles,

construction machinery, agricultural machinery, construction machinery, light industrial machinery and

aerospace, military and high-speed trains. Self-lubricated bearings have become one of the key industries in the

fields of train, large-scale construction machinery, high-speed and high-precision CNC machine tools and so on.

Company WebSite:

www.csb.com.cn

Innowep

INNOWEP is a German manufacture of testing machines for the evaluation of material durability, friction and wear, fatigue, and complex human physiology based haptic study and fingertip & hand abrasion. It is headquartered in Wuerzburg. Germany and several subsidiary offices in Asia. Together with two offices in China. AMT Beijing and AMT Nanjing. We supply continuously with German quality of fatigue test bench for the components used in the electric cars, including bearing , gear, gearbox, and etc.

PERA

PERA Corporation, dedicated to the development of R&D technology,

PERA provides advanced R&D technology, software, and services to companies’ product R&D

cycle, helping customers by adding technical value and enhancement to their product,

and improving customers’ core competitiveness.

Company WebSite:

www.peraglobal.com

Suzhou Industrial Park Xinkai Precision Fasteners Co., Ltd

Suzhou Industrial Park Xinkai Precision Fasteners Co., Ltd was founded in 2003,

specializing in R & D, manufacture and sale of all types of fasteners and precision

machining parts, with a total construction area of about 20,000 square meters.

The company is equipped with advanced production and test equipment. Products category:

Automotive fasteners, Rivet, Precision machining parts, DIN、JIS、ANSI、GB、BS

Standard fasteners and various customized components, we also design and produce special

fasteners for customer. We are so proud to be the qualified supplier to serve

the world leading automotive manufacturers , with cutting-edge technology in different

application scenario.

Our company has been certified by IATF 16949 : 2016, ISO 9001 : 2015, ISO 14001 :

2015 and ISO/IEC 17025 : 2005 systems. We are dedicated to providing our customers with

superior products and services by continuous improvement.

Company WebSite:

www.xinkainet.com

Beijing Oriental Jicheng Co. Ltd.

Initiated by OSIC HOLDINGS, one of the largest comprehensive groups of Chinese Academy of

Sciences (CAS) in 2000, Beijing Oriental Jicheng Co. Ltd., (short for BOJ) is a high-tech

enterprise registered in Zhongguancun Science Park. Under the great support of all

shareholders and relevant government departments, BOJ has successfully listed in A-share

market of Shenzhen Stock Exchange, with the stock code 002819, in November, 2016.

After 16 years’ vigorous growth, BOJ has a new startup in new platform.

BOJ is one of the leading companies in testing instrument technology rental business in

China. We are also proud of that we are very few comprehensive service providers which

can provide a full range of services including instrument sales, rental, system

integration and related technical services. The integrated service mode of

“Business + Product + Service” created by BOJ has become an industry model.

Along with the development of business, we valued our brand as well. Therefore,

BOJ gained a good reputation in goodwill, professionalism, customer services,

business growth and industrial responsibilities. In addition, BOJ has built up

an excellent marketing service network, abundant industrial chain resources and

solid technological base. Headquartered in Beijing, BOJ has branch offices in Shanghai,

Nanjing, Suzhou, Shenzhen, Xi’an, Wuhan, Chengdu, etc. with its services covered more than

30 large and medium cities all over the country. Established and grew in

Zhongguancun Science Park, Beijing, BOJ has now become a powerful service provider in

the field of integrated service of electronic test & measurement in China after many

years’ hard working.

Company WebSite:

www.xinkainet.com

Balluff

Founded in Neuhausen auf den Fildern in 1921, Balluff now has 3,600 employees and stands

for innovative technology, quality and cross-industry experience in industrial automation.

As a leading sensor and automation specialist, this 4th generation family company offers

a comprehensive portfolio of innovative sensor, identification and network solutions as

well as software for integrated system and solutions.

In 2020, the Balluff Group reported a turnover of around 409 million euros.

In addition to the company headquarters in Neuhause auf den Fildern,

Balluff has distribution, production and development sites all around the globe,

and is represented by 38 subsidiaries and further branches.

Schenck Shanghai Machinery Corp. Ltd.

Schenck Shanghai Machinery Corp. Ltd. affiliated to the renowned international

corporate——the Dürr Group, is a 100% German investing and holding company established

in 1999. Schenck Shanghai synchronizes the same technical database with German

Headquarter to achieve an international technology level through product property as

an outstanding high-tech enterprise. Schenck manufactures in China and even develops

products with Germany headquarter for the Chinese market. Shanghai has been a location

among many, but the very center of Asian business.

Shanghai Schenck machinery mainly focus on Measuring and Processing System with 3 key

business units in China:

Balancing and Diagnostic System(BDS): As a balancing machine initiator and leader,

Schenck has been engaged in the research and application of balancing technology.

Schenck actively provides customer balancing and inspection, balancing service and

consulting.

Vision Tool

Vision Tool is specialized in designing and building stamping tool, check fixture and

weld gauge for the automotive industry. The company was founded in 1999 and changed

name in 2005. Our stamping tool mainly for automotive Body-in-White, Chassis, Seating,

Roof, Skin Parts and so on, mainly serving the European and American Markets.

Our clients include the renowned Tier-1s and OEMs in the global automotive industry,

such as PSA, Volvo, Ford, Audi, Cosma, Kirchhoff, Tower, Snop, CIE, Martinrea,BYD,

and so on.

Vision Tool operates four Business Modules:Progressive Tool, Tandem Tool, Transfer Tool,

Gauge & Fixture. Our Strengths include Capability, Capacity,Competitive Price,

One-Stop Shopping,Pre&After Sales Services.

Wuxi Rely-Measure Measurement Technology Co.,Ltd.

Wuxi Rely-Measure Measurement Technology Co.,Ltd. was founded in 2013, which focuses on

sales, service and system automation integration of optical inspection machines.

We have many high qualified customers in automotive and other manufacturing industries,

as the Master Distributor of RX SOLUTIONS in China, Wuxi Rely-Measure will take the full

responsibility of Sales/Installation/Service work of RX SOLUTIONS’ Industrial CT machines.

The key products of our company are,

1.Italy ViciVision Optical Measurement Machine

The equipment uses optical non-contact measurement method, which is mainly used for the

full-size detection of shaft parts. It is widely used in automobile, military industry,

aerospace, medical and general industrial fields, moreover it can be directly applied to

the production line. The highest accuracy can reach 1um, greatly improves production

efficiency.

2.Italy Metrios Flash Measurement Machine

As an upgraded equipment of traditional imager, it works without positioning,

and uses optical method to quickly measure the size of flat parts. It has the most

complete light source configuration, and also has best performance in the market.

3.France RX Solutions Industrial CT

With power below 300kV, RX Solutions can provide real scanning resolution up to 400nm,

and can be equipped with up to three ray sources in one equipment at the same time,

providing the best nondestructive testing scheme, which can be widely used in scientific

research, electronics, automobile, aerospace and related industrial fields.

Company WebSite:

www.rely-measure.com